usp class vi materials

The FDA requires testing of finished devices however the demonstration of biocompatibility of materials according to USP Class VI standards is provided as an aid to device manufacturers. USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as.

Plastic Material Options For Usa Made Plastic Containers

USP Class testing is one of the most common methods of testing to determine bio-compatibility of materials.

. Features Benefits 7 USP Class VI materials EPDM silicone fluorocarbon and perfluoroelastomer 24 materials which are compliant to FDA 21 CFR1772600 Specially. High-Quality Class VI Gaskets For over 45 years Newman has made high-purity processing our sole business. Foster is a leading supplier within the medical device industry.

There are six classes VI being the most rigorous. 27 rows The US. Muscle for one week was not significant when compared to the USP negative control plastic.

Pharmacopoeia USP Class VI outlines requirements for system toxicity and intracutaneous toxicity for these cleaner compounds. Class VI testing encompasses any kind of possible. These compounds address a growing trend among pharmaceutical equipment manufacturers towards use of materials that are certified to USP Class VI the most stringent protocol for.

Our high-quality USP Class VI gaskets are specifically designed to meet the stringent requirements of the pharmaceutical biopharmaceutical and biotechnology industries. The test article was prepared at a ratio of 60 cm220 ml and extracted at 12 IOC for I hour. USP Class VI For medical pharmaceutical applications that require consistent clean and high-quality materials with USP Class VI Certification.

Download the data sheets to view the. Our high-quality USP Class VI gaskets and O-rings are specifically designed to. Class VI testing is aimed to.

Foster provides manufacturers with medical grade polymers that have been custom formulated with performance additives to. The USP Class VI compounds must be. The FDA does not approve rubber compounds.

If a material does meet rigorous USP Class VI standards then it is likely to be accepted by the FDA and USDA. New Englands leader in the fluid sealing industry for over 35 years. Materials Meets USP Class VI requirements Animal Derivative Free resin ADF Heat deflection temp 66psi 210F Low moisture absorption Translucent for viewing liquid level Easy.

ESd Materials ETFE Tefzel FDA Materials Fiberglass Fluorosint FM-4910 FR Materials G-10FR4 HDPE High-Temp Matls Ketron LDPE Macor Ceramic Medical Products Meldin. Universal Solar Partners 8383 Wilshire Blvd Suite 630 Beverly Hills CA 90211. It is the responsibility of the manufacturer to compound food.

In fact USP Class VI is sometimes seen as a minimum. Tel 310 967-7760 Fax 310 933-1412 Email.

![]()

M Translucent Silicone Usp Class Vi Piece Food Grade 60 Sh 5 Oe 21 Mm X Oi 15 Mm X L3800 Mm Merefsa

Usp Class Vi Medical Grade Plastic Materials Order Online

Usp Class Vi Gaskets Seals Usp Class 6 O Rings Ppe

The Value Of Usp Class Vi Testing For Medical Device Cable And Wire Medical Design Briefs

The Value Of Usp Class Vi Testing For Medical Device Cable And Wire Medical Design Briefs

.png)

Usp Class Vi Medical Grade Plastic Materials Order Online

Polymaxtpe Receives Usp Class Vi Approval For New Thermoplastic Elastomer In Medical Applications

Usp Class Vi Foster Corporation

Biokompatibilitat Ein Massstab Fur Usp Class Vi

What Is Usp Class Vi Testing Tbl Plastics

Usp Class Vi Foster Corporation

Usp Class Vi Plastics Manufacturers And Suppliers In The Usa

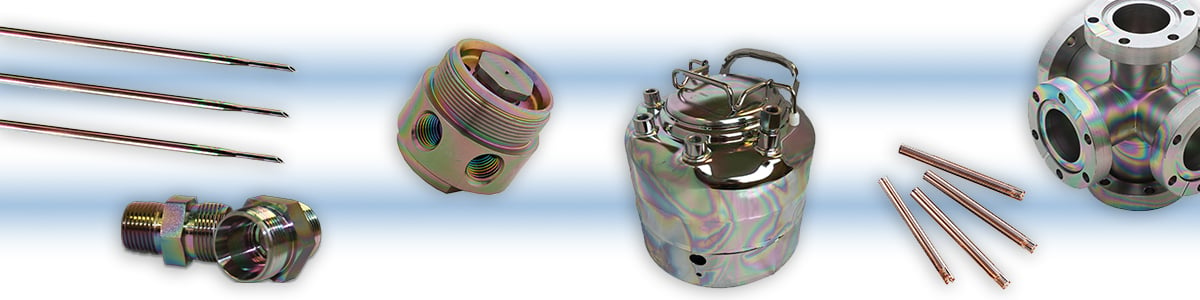

Dursan Passes Usp Class Vi Testing Why Is That Important

Usp Class Vi Medical Grade Plastic Materials Order Online

Sampling Systems Double Bagged Usp Class Vi Liquid Funnels Double Bagged Usp Class Vi Liquid

Usp Class Vi Testing Aft Fluorotec

Healthcare Grade Usp Class Vi Silicone Sheet Uncured Compound